Mold Making Services: The Backbone of Modern Manufacturing

In the ever-evolving landscape of manufacturing, precision, speed, and scalability are the cornerstones of success. One key process that plays a crucial role in achieving these goals is mold making services. These services are fundamental to producing components for a wide range of industries—from automotive and aerospace to medical devices and consumer electronics.

As companies across the globe push for faster product development and high-quality mass production, the demand for reliable mold making services has skyrocketed. This article explores everything from the basics of mold making to its industry applications, benefits, and how to select the right provider.

What Are Mold Making Services?

Mold making services involve the design, fabrication, and testing of molds used to shape raw materials—primarily plastics and metals—into finished or semi-finished components. These molds are often custom-made for specific products and are used in high-volume production to ensure consistency, quality, and cost-efficiency.

Common techniques within mold making include:

- Injection molding for plastic parts

- Die casting for metal components

- Blow molding for hollow containers

- Compression molding for rubber and composites

See also: Smart Office: Redefining the Future of Workspaces Through Technology

Key Steps in the Mold Making Process

Mold making is a highly technical and multi-phase process. Below is a step-by-step outline of what typical mold making services include:

1. Design and Engineering

Using CAD software, engineers create detailed designs based on client specifications. A mold flow analysis may also be conducted to assess part quality and production feasibility.

2. Material Selection

The choice of mold material—usually steel (like P20 or H13) or aluminum—depends on the volume and type of production. Steel offers durability, while aluminum is cost-effective for prototypes and low-volume runs.

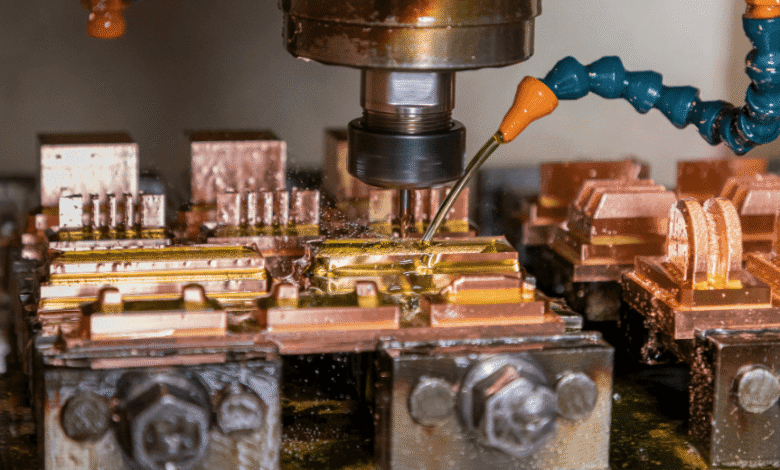

3. Machining and Tooling

Advanced equipment such as CNC machines and EDM systems shape the mold cavities with high precision.

4. Assembly and Polishing

After machining, all components are assembled and finished. Polishing ensures smooth surfaces, which can affect the final product’s appearance and function.

5. Testing and Trials

Trial runs using actual production material are performed to validate the mold. Modifications may be made before final approval.

Advantages of Professional Mold Making Services

Using professional mold making services offers several benefits that contribute to product excellence and operational efficiency.

✔ Precision and Consistency

With tight tolerances and accurate replication, molds ensure that every component produced meets exact specifications.

✔ Speed to Market

Once a mold is approved, companies can produce thousands of identical parts quickly, reducing time-to-market for new products.

✔ Cost Efficiency

Though molds can be expensive upfront, the per-unit cost decreases dramatically in high-volume production.

✔ Material Flexibility

Mold making services support a wide array of materials—from thermoplastics and metals to silicone and bio-resins.

Industries That Rely on Mold Making Services

1. Automotive

Car manufacturers use molds to produce everything from engine components to dashboard panels, contributing to both aesthetic and functional features.

2. Medical Devices

High-precision molds are essential for creating disposable syringes, implant parts, diagnostic tools, and other medical supplies.

3. Consumer Electronics

Casings, buttons, connectors, and internal plastic parts for phones, laptops, and other electronics are manufactured using custom molds.

4. Food and Beverage

Blow molds are used to produce plastic bottles, caps, and containers in large quantities for beverage and food packaging.

5. Aerospace

Complex geometries and high-strength materials in aerospace require specialized mold making services to meet strict quality standards.

Choosing the Right Mold Making Services Provider

The success of your product depends heavily on the quality of the mold used. Here are some criteria to evaluate when choosing a mold maker:

📌 Experience and Reputation

Work with providers that have a proven track record in your industry. Customer reviews, testimonials, and case studies can offer valuable insights.

📌 Technical Capabilities

Ensure the service provider has advanced CNC machines, software tools, and skilled technicians to handle complex mold designs.

📌 Design Support

Look for companies that offer design optimization and DFM (Design for Manufacturability) analysis to reduce revisions and waste.

📌 Lead Time

Turnaround time can affect your go-to-market strategy. Ask for clear timelines and buffer periods for testing and revisions.

📌 Quality Assurance

ISO certifications, in-house testing labs, and detailed inspection protocols are signs of a quality-conscious provider.

In-House vs Outsourced Mold Making Services

Businesses often face the decision of whether to build molds in-house or outsource to a specialized service. Here’s a quick comparison:

| Factor | In-House | Outsourced |

| Initial Cost | High (equipment and labor) | Lower capital investment |

| Expertise Needed | Requires skilled staff | Expertise provided by the service provider |

| Speed | May be faster for urgent changes | Faster for complex, large-scale projects |

| Quality | Variable, depending on internal team | Typically high due to specialization |

Future Trends in Mold Making Services

As industries demand even more customization and efficiency, mold making services are adapting through innovations:

🔬 Additive Manufacturing Integration

Some service providers now use 3D printing to create prototype molds, significantly speeding up development cycles.

🧠 Smart Tooling

Embedded sensors in molds help monitor temperature, pressure, and wear during production, enabling predictive maintenance.

🌍 Eco-Friendly Practices

Recyclable materials, energy-efficient machining, and reduced waste processes are gaining traction in the mold-making ecosystem.

💻 Cloud-Based Collaboration

Cloud platforms are enabling real-time sharing of CAD files, design reviews, and project tracking between international teams and mold makers.

Conclusion

From product prototypes to mass production of industrial and consumer goods, mold making services are the foundation of modern manufacturing. These services enable precision, repeatability, and cost-effectiveness on a scale unmatched by manual fabrication methods.

Whether you’re a startup launching a new plastic component or an established company seeking to scale production, investing in the right mold making partner is critical. By focusing on quality, technical capability, and industry reputation, you can ensure your products are molded for success.