Enhancing Fire Safety with Class 0 Foam and Fireseal Solutions

Introduction

In environments where fire safety and sound control are paramount, choosing the right materials can make all the difference. Among the various fire-resistant and sound-absorbing materials available, Class 0 Foam stands out for its unique properties that ensure both safety and functionality. This article explores the benefits, applications, and technical features of Class 0 Foam, along with the complementary role of Fireseal systems, offering a comprehensive insight for professionals in construction, automotive, marine, and industrial sectors.

1. What is Class 0 Foam?

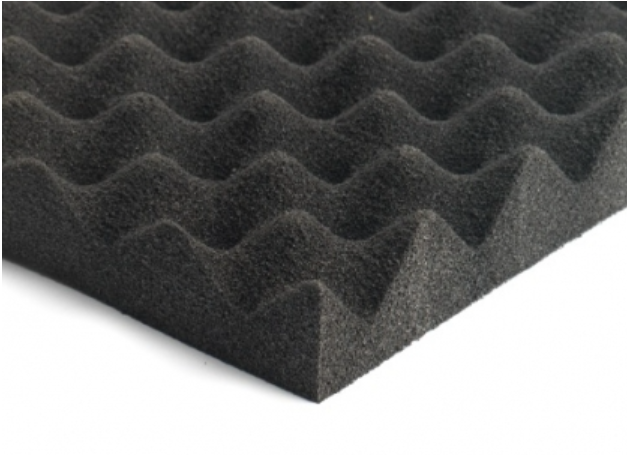

Class 0 Foam is a specially treated polyurethane foam designed to resist fire hazards in high-risk environments. Unlike regular foams, Class 0 Foam is chemically treated with mineral compounds that give it a nil burn rate, meaning it does not ignite or support combustion under standard fire test conditions. This fire-resistant property makes it ideal for use in areas that require stringent fire safety standards.

Beyond fire resistance, Class 0 Foam is chemically inert and non-dusting, ensuring it does not release harmful particles into the environment. Its flexibility allows it to be easily applied to curved or irregular surfaces without compromising its structural integrity or safety features.

2. Key Benefits of Class 0 Foam

Class 0 Foam offers a wide array of advantages, making it an excellent choice for fire safety and acoustic applications:

- Nontoxic and Environmentally Friendly: The foam is free from harmful chemicals such as CFCs and HCFCs, ensuring a safe environment for users.

- Flexibility and Ease of Installation: Easily cut and shaped, it fits complex geometries and surfaces.

- Fire-Resistant: It meets strict fire safety classifications with a nil burn rate.

- Sound Absorption: Apart from fire resistance, Class 0 Foam excels in acoustic performance, especially in controlling noise within engine rooms, heavy vehicles, and industrial spaces.

- Variety of Forms: Available as sheets, roll foam, or profiled foam, with options for self-adhesive backing for simple application.

- Durability: Resistant to erosion and non-fibrous, ensuring longevity even in air movement or high-heat environments.

These attributes combine to make Class 0 Foam not just a safety material but also a functional solution for soundproofing and vibration damping.

3. Fireseal: Complementing Class 0 Foam for Enhanced Safety

While Class 0 Foam is exceptional in resisting fire and reducing combustion risks, Fireseal systems act as complementary solutions, sealing gaps and joints to prevent the spread of fire, smoke, and toxic gases through structural openings.

Fireseal products, often used alongside Class 0 Foam in construction and industrial applications, enhance the overall fire safety of buildings and vehicles by maintaining compartmentalization during fire incidents. When integrated properly, Fireseal and Class 0 Foam create a robust barrier that not only absorbs sound but also impedes fire propagation, ensuring greater safety and compliance with fire codes.

4. Acoustic Performance of Class 0 Foam

A standout feature of Class 0 Foam is its superior acoustic properties. Its open-celled structure efficiently absorbs mid to high-frequency sounds, reducing echo and reverberation in enclosed spaces. This makes it especially valuable in:

- Engine Rooms and Generator Canopies: Where machinery noise can be overwhelming.

- Heavy Vehicles: Providing comfort through noise reduction.

- Industrial Facilities: Minimizing noise pollution and enhancing worker safety.

The high-density Class 0 Foam variant offers exceptional sound absorption, while special fabric facings like Silver dolphin fabric are recommended for automotive interiors such as cabin trim panels and headliners. These facings not only improve durability but also add aesthetic value.

Moreover, marine-grade versions of Class 0 Foam come with foil facings and PVC barriers to withstand high heat and harsh environments while acting as efficient sound barriers.

5. Versatility and Customization

One of the advantages of Class 0 Foam is its adaptability. It can be supplied with an extensive range of facing materials and surface coatings to meet specific application requirements. For instance:

- Composite Forms: Incorporating lead foil or polymeric barriers for enhanced sound and fire resistance.

- Spray-Applied Coatings: For additional surface protection and performance.

- Self-Adhesive Options: Simplify installation on difficult surfaces.

These options make Class 0 Foam a versatile material suitable for a variety of sectors including construction, automotive, marine, and industrial equipment manufacturing.

See also: How Businesses Can Save Money on Utility Bills?

6. Applications of Class 0 Foam and Fireseal

Given its unique properties, Class 0 Foam finds extensive use across multiple industries:

- Construction Sector: Used in walls, ceilings, and partitions to meet fire safety regulations while improving acoustic comfort.

- Automotive Industry: Installed in cabins and engine compartments for noise reduction and fire resistance.

- Marine Applications: Applied in engine rooms and living quarters where fire safety and soundproofing are critical.

- Industrial Equipment: Used inside heavy machinery and generator canopies to protect workers from excessive noise and potential fire hazards.

Additionally, when paired with Fireseal products, these materials provide a complete fire safety and acoustic solution, enhancing both protection and comfort.

7. Installation and Maintenance Tips

To maximize the benefits of Class 0 Foam and Fireseal, proper installation and upkeep are essential:

- Surface Preparation: Ensure surfaces are clean and dry before application.

- Cutting and Shaping: Use sharp tools to cut foam to fit complex shapes without compromising edges.

- Adhesion: Use the appropriate adhesive backing or mounting systems recommended by the manufacturer.

- Maintenance: Regularly clean foam surfaces with a vacuum or soft brush to remove dust and debris. Avoid water and harsh chemicals to preserve integrity.

- Inspection: Periodically inspect Fireseal joints and foam for damage or degradation, especially in high-heat or humid environments.

Following these guidelines will ensure that Class 0 Foam and Fireseal systems continue to perform effectively over time.

Conclusion

In environments where both fire safety and sound control are critical, Class 0 Foam emerges as an exceptional solution, combining fire resistance with acoustic performance. Treated to achieve a nil burn rate, this foam not only enhances safety but also offers flexibility, ease of installation, and durability. When used alongside complementary Fireseal products, it creates a comprehensive barrier against fire, smoke, and noise.

Whether you are involved in construction, automotive design, marine engineering, or industrial manufacturing, investing in Class 0 Foam and Fireseal solutions ensures compliance with safety standards while improving environmental comfort. For tailored advice and to explore product options, contacting specialized providers such as Acoustafoam is highly recommended.

Prioritize safety and performance by integrating Class 0 Foam and Fireseal into your next project — a smart choice for today’s demanding fire and acoustic standards.